-

Ai-empowered

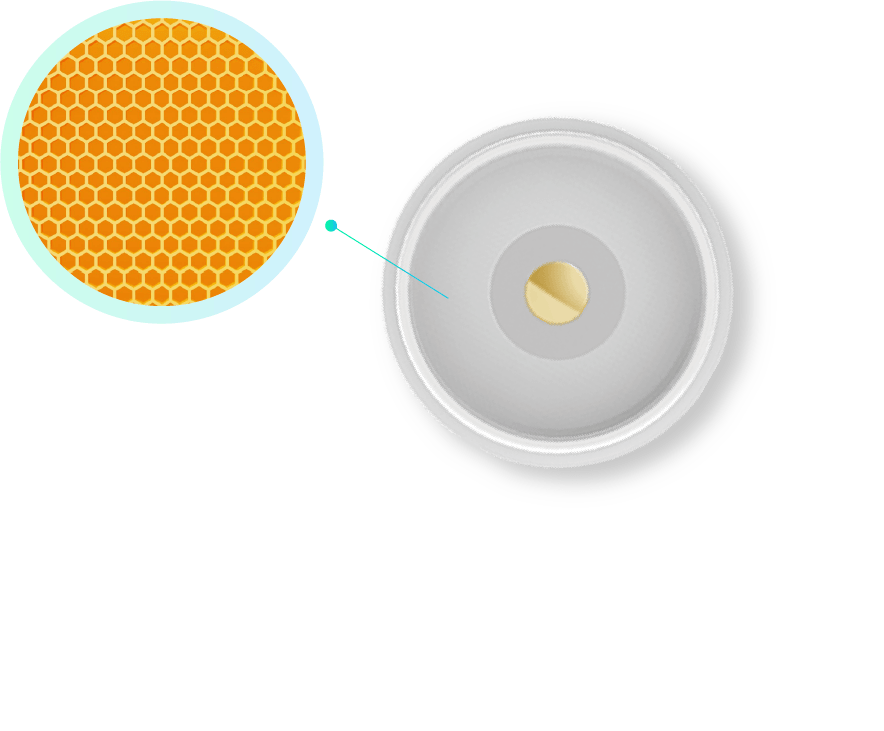

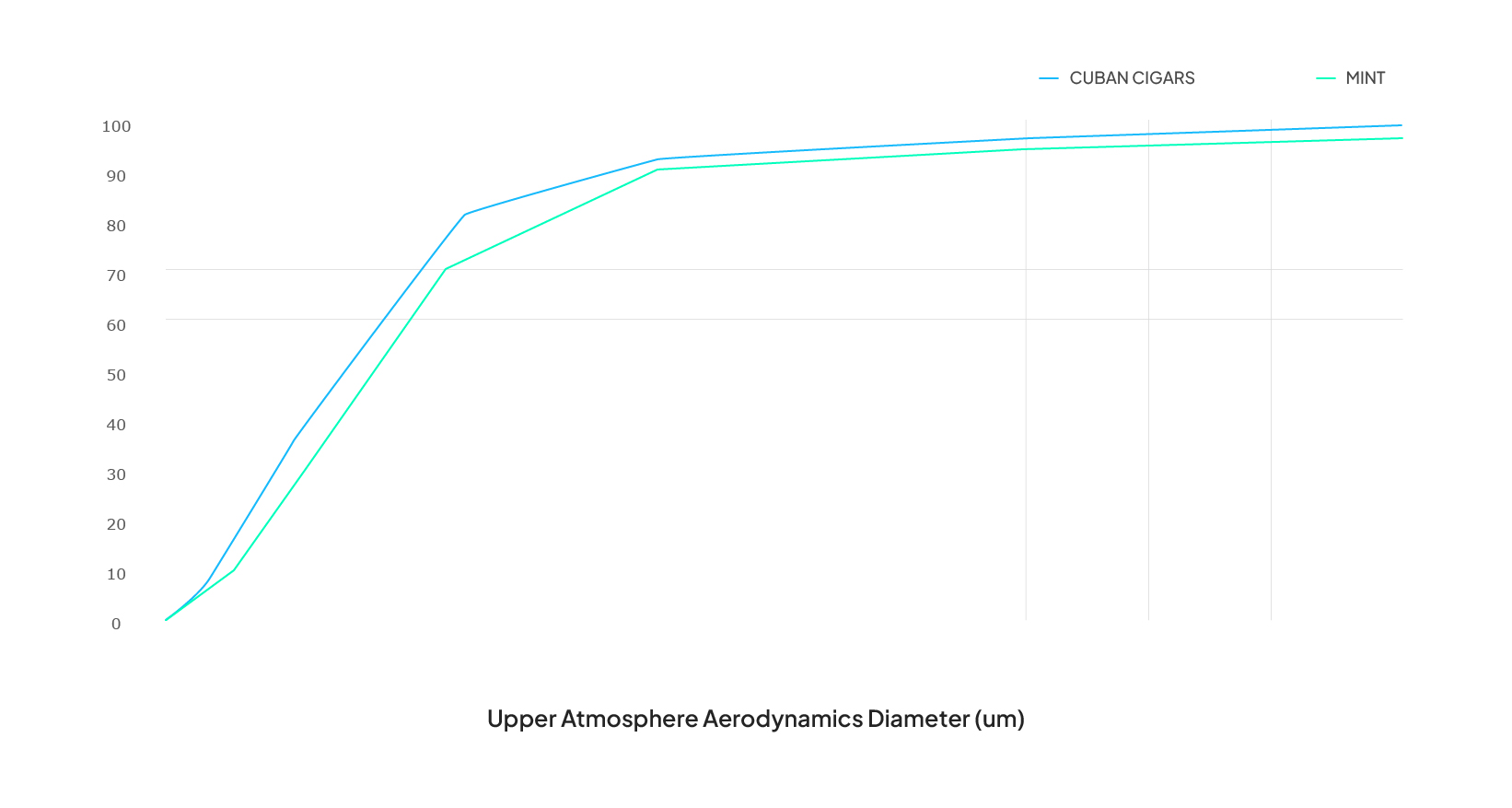

The particle size can be adjustedto the drug parameters to ensureoptimum preventive or therapeuticeffect

-

Rust-free

Rust-free because of good acid and corrosion resistance

-

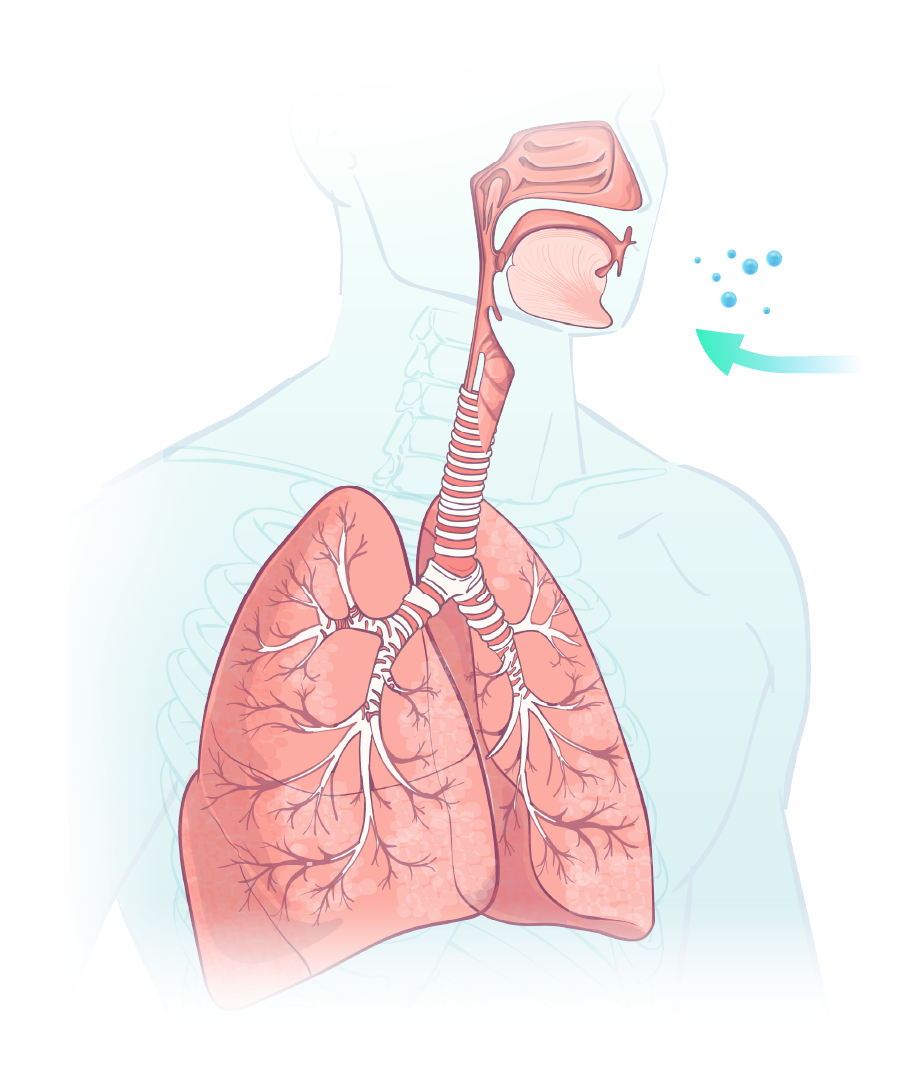

Extreme Nebulization Particle Size

The exclusive Vplus patent allows for precise dosing and dosing while maintaining the finest atomization

-

Remains Unbreakable

The material is bio-elastic and does not crack easilyunder vibration